The CPRO (Circular Plate Reverse Osmosis) Disc technology is a PATENTED design. It is a very economic and efficient technology for the treatment of effluent and wastewater. The CPRO technology is a patented and proven membrane technology with a plate and frame design suitable for overcoming the problems faced in spiral-wound reverse osmosis processes. CPRO systems were developed to remove dissolved solids (TDS), COD, BOD, and many other impurities and are most often associated with RO systems. The suspended solids and organic load carried in the feed water cannot be trapped or easily settle out inside the membrane module and hence minimize the need for costly pre-treatment such as chemical precipitation, biological processes, stage-wise filtration, and ultrafiltration, which are commonly used in spiral-wound membrane systems. The CPRO system minimizes scaling and fouling of membranes due to its short feed flow and high packing density, which increases the life of the membranes and reduces replacement costs. CPRO systems can handle higher SDI (Silt Density Index) and high COD, BOD content, and are therefore best equipped for wastewater and effluent treatment applications. The CPRO Modules are compact in size, flexible in operation, and provided with easy access to all membranes for inspection, replacement, and other activities.

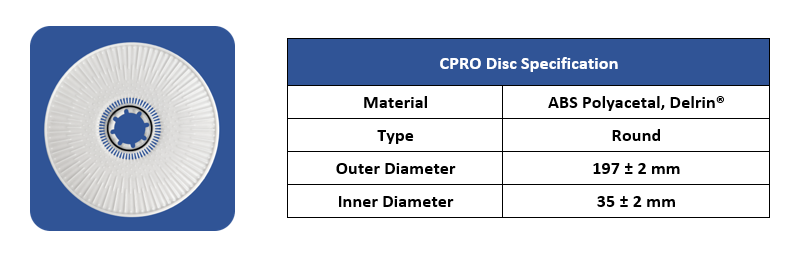

The CPRO module consists of a pressure tube, membrane cushions, and hydraulic discs, which are held together by a central tension rod. The basic unit is constructed as a sandwich of flat membrane sheets, known as membrane cushions, placed alternately between hydraulic discs. These membrane cushions and hydraulic discs are inserted onto a tie rod and enclosed within a pressure tube. Both ends of the tie rod are secured with end flanges fitted with lip seals to meet operational requirements.

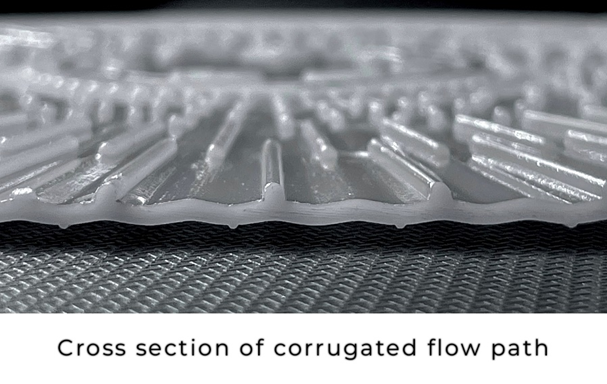

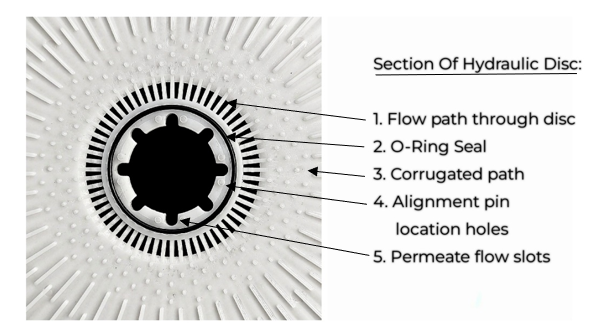

Due to the specialized construction of the hydraulic discs and membrane cushions, a flow is formed between them, where the raw solution gets concentrated. Individual channels within the module are connected through openings in the discs, causing the feed water flow to redirect across the membrane cushions, alternating from the inside towards the outside and then reversely. As the feed water flows through this arrangement, a portion of it permeates through the two surrounding membrane layers into the permeate slot, leaving behind dissolved and particulate contaminants rejected by the membrane. The filtered water collected in the permeate slots moves toward the central collector tube, while the portion of water that does not permeate continues to flow across the membrane surface, becoming increasingly concentrated with rejected contaminants. This concentrate stream exits the module parallel to the concentrate tube, where it is finally collected and prepared for disposal.

The membrane cushions are made of two single membranes with an intermediate fleece sheet (spacer) featuring an octagonal construction. The outer edges of the membrane cushion are sealed by ultrasonic welding.

The patented Hydraulic Disc CPRO design enhances water flow efficiency and reduces clogging and concentration build-up. The feed flow path and high packing densities ensure smooth water movement, minimizing pressure drops. The concentric pin alignment speeds up installation, allowing for easy matching of dots on adjacent discs. The corrugated shape of the design offers enhanced structural strength to withstand higher pressure effectively. Additionally, the spaces between the corrugations provide increased volumetric capacity, allowing water to pass through more efficiently.

This design minimizes pressure drop across the system and ensures that suspended matter has sufficient space to move through, particularly in the final area, thereby improving overall flow. In summary, this design optimizes water flow and simplifies installation, making it a practical solution for water filtration.

AREAS OF APPLICATIONS